Laser Cutting Charges & Cost per mm in India: Complete Price Guide

- Home

- Laser Cutting Charges & Cost per mm in India: Complete Price Guide

Introduction

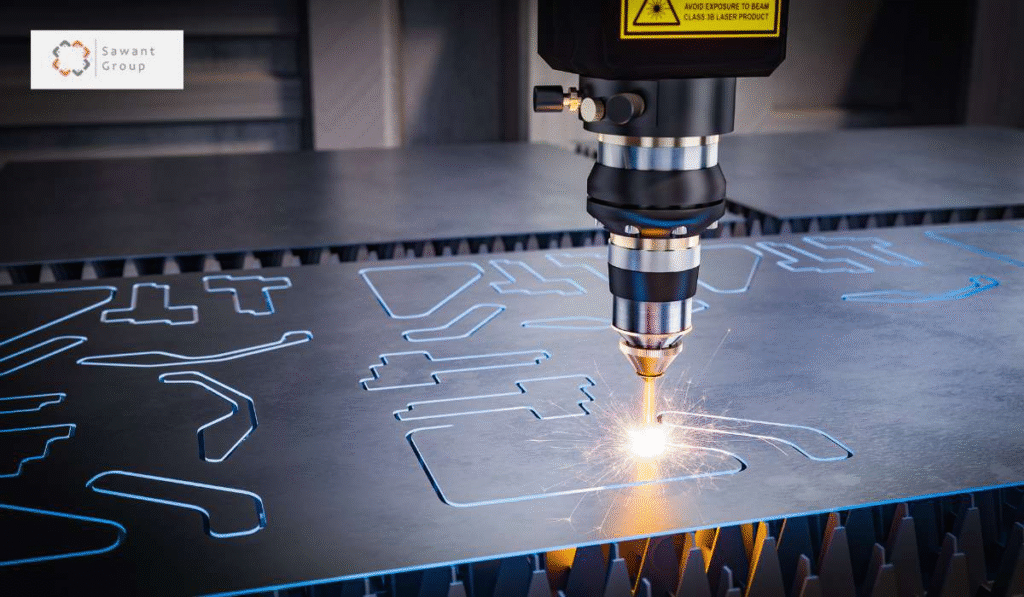

Laser cutting is one of the most advanced and efficient methods used in today’s manufacturing industry. From stainless steel to aluminium, businesses across automotive, fabrication, construction, and engineering sectors rely on this technology for precision cutting and cost efficiency.

But when it comes to outsourcing the job, most clients ask a common question: “What are the laser cutting charges in India?”

To help you, this guide covers everything from laser cutting cost per mm in India to the key factors that affect the price of laser cutting. By the end, you’ll understand how pricing is calculated, what impacts the rates, and why laser cutting is often the most cost-effective solution for businesses.

What are Laser Cutting Charges in India?

Laser cutting charges are the fees that service providers charge for cutting materials using high-powered laser machines. Unlike manual or traditional cutting methods, laser cutting offers:

- Higher accuracy

- Faster production

- Minimal material wastage

- Complex design capabilities

These charges usually depend on:

- The material being cut (steel, aluminium, brass, copper, etc.)

- Thickness of the sheet

- Total cutting length (measured in mm or meters)

- Design complexity (simple straight lines vs. intricate patterns)

So, the price of laser cutting is not fixed—it varies from project to project.

Laser Cutting Cost per mm in India Explained

Most service providers calculate charges per mm of cutting length. Here’s a general breakdown of laser cutting cost per mm in India:

| Material | Thickness Range | Approx. Cost per mm (₹) |

| Stainless Steel | 1mm – 20mm | ₹0.50 – ₹3.00 |

| Mild Steel | 1mm – 25mm | ₹0.40 – ₹2.50 |

| Aluminium | 1mm – 15mm | ₹0.60 – ₹3.50 |

| Brass / Copper | 1mm – 10mm | ₹0.70 – ₹4.00 |

💡 Note: These are estimated ranges. The exact laser cutting charges will depend on your order size, location, and machine type.

Factors That Affect the Price of Laser Cutting

The price of laser cutting isn’t universal—it changes based on multiple factors. Let’s look at the main ones:

- Material Type & Thickness

- Harder and thicker materials take more power and time, increasing the cost.

- For example, cutting 20mm stainless steel is more expensive than cutting 2mm aluminium.

- Harder and thicker materials take more power and time, increasing the cost.

- Cutting Length & Design Complexity

- Straight cuts are cheaper than detailed patterns.

- Intricate designs require slower speeds and more machine time.

- Straight cuts are cheaper than detailed patterns.

- Machine Type

- Fiber lasers are faster and more energy-efficient than CO₂ lasers.

- This efficiency often reduces the laser cutting cost per mm in India.

- Fiber lasers are faster and more energy-efficient than CO₂ lasers.

- Quantity of Work

- Bulk orders usually get lower per mm charges.

- Small, custom jobs may cost more per unit.

- Bulk orders usually get lower per mm charges.

- Location & Industry Rates

- Prices vary across cities and service providers.

- Metropolitan areas often have slightly higher laser cutting charges.

- Prices vary across cities and service providers.

Price Comparison: Laser Cutting vs Traditional Cutting

Many businesses wonder if laser cutting charges are worth it compared to older methods like plasma or oxy-fuel cutting.

Here’s the reality:

- Laser Cutting Advantages:

- Accuracy within microns

- Clean edges, little to no finishing required

- Ability to cut complex shapes

- Less material wastage

- Accuracy within microns

- Traditional Cutting Drawbacks:

- Rough edges that require finishing

- Higher chances of errors

- More wastage and slower turnaround

- Rough edges that require finishing

When you add up these factors, the price of laser cutting often turns out to be cheaper in the long run.

Real-World Example of Laser Cutting Charges

Imagine you need 500 parts made of 3mm stainless steel, each with a cutting length of 200mm.

- Laser Cutting Cost Calculation:

- Cost per mm = ₹1.00 (for 3mm stainless steel, approximate)

- Cutting length = 200mm × 500 parts = 100,000mm

- Total = 100,000 × ₹1.00 = ₹1,00,000

- Cost per mm = ₹1.00 (for 3mm stainless steel, approximate)

Now, if the same job is done by traditional cutting, you’d also need grinding, polishing, and finishing, which add to the cost. That’s why more industries are shifting to laser cutting services.

How Sawant Group Offers Affordable Laser Cutting Charges

At Sawant Group, we combine advanced technology with cost-effective solutions. Our Trulaser-3060 Fibre machine can cut stainless steel up to 40mm thickness, providing both speed and precision.

Here’s why clients prefer us:

- Competitive laser cutting cost per mm in India

- Capability to cut stainless steel, aluminium, brass, copper, and more

- Quick turnaround time for bulk orders

- Experienced team ensuring top-notch quality

📞 Contact Sawant Group today for a free quote and get the best price of laser cutting tailored to your project.

FAQs on Laser Cutting Charges in India

Q1. What is the average laser cutting cost per mm in India?

It usually ranges between ₹0.40 to ₹4.00 per mm depending on material type, thickness, and complexity.

Q2. Why do laser cutting charges vary between providers?

Because factors like machine type, operator expertise, bulk quantity, and city-based costs impact pricing.

Q3. Is laser cutting cheaper than plasma cutting?

Yes, while per mm cost may look higher, laser cutting saves on finishing, reduces wastage, and ensures higher accuracy—making it cost-effective overall.

Q4. What is the minimum order size for laser cutting services?

Some providers accept even single prototype jobs, but charges per mm may be higher for smaller orders.

Q5. Which industries benefit the most from affordable laser cutting charges?

Automotive, aerospace, fabrication, furniture, construction, and signage industries.

Conclusion

To summarize, laser cutting charges depend on material type, thickness, cutting length, and design complexity. The laser cutting cost per mm in India usually ranges from ₹0.40 to ₹4.00 per mm, but the actual price of laser cutting will vary depending on your project needs.

When compared to traditional methods, laser cutting may appear slightly expensive per mm, but it offers unmatched precision, reduced wastage, and faster production—saving costs in the long run.

If you want affordable, reliable, and high-quality laser cutting services in India, Sawant Group is your trusted partner.

👉 Contact us today to get a customized quote for your project.

Leave A Comment